86-0536-3090222

ISO9001-2008 Approved Peanut Dryer

Product Parameters:

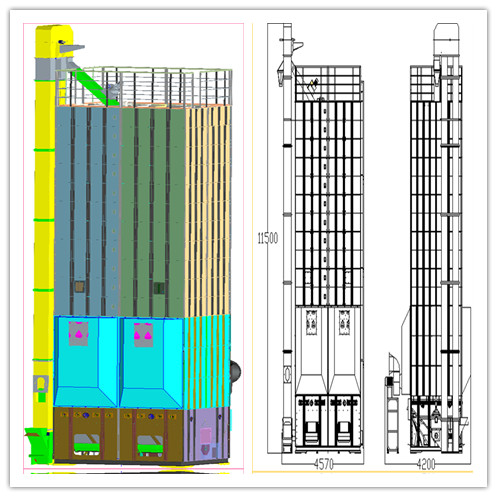

| Technical Parameters | Units | 5HRH-35 | |

Grain type &Processing capacity | Paddy | kg | 2000-35000 |

| Wheat | kg | 2000-38000 | |

| Draft fan | Model | / | LSHG-6A |

| Form | / | Centrifugal Fan | |

| Diameter | mm | Φ600 | |

| Speed | r/min | 1450 | |

| Blowing rate | m3/h | 25000-30000 | |

| Total pressure | Pa | 950 | |

| Hot blast stove | Form | / | Automatic temperature control |

| Ignition system | / | Manual ignition | |

| Fuel | / | Biochar / Coal | |

| Fuel consumption | kg/h | 120/60 | |

| Total Power | KW | 19.37 | |

| Dimention | mm | 4570×4200×11500 | |

| Performs | Feeding time | min | 50-60 |

| Discharging time | min | 60-70 | |

| Drying rate | %/h | 0.6-1.2 | |

| Safety device | / | Full grain alarm, overload protection device, overheat sensor, control fuse, pressure sensor, combustion engine off alarm. | |

| Note | The actual drying rate will vary with the ambient temperature, the hot air temperature, the relative humidity, the material variety and the moisture content of materials. | ||

Product Description

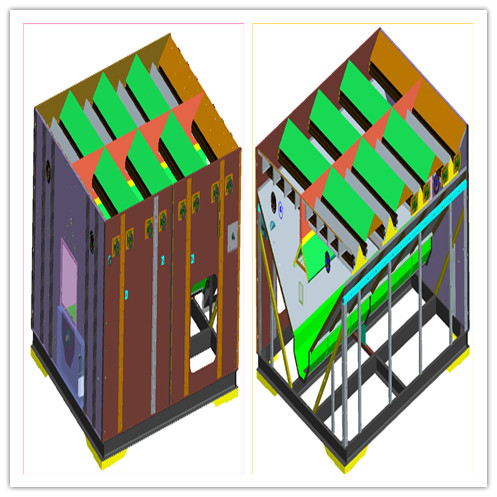

A. Grain layer:

The structure design of eight shifting wheels is adopted, which is divided into parts, the internal parts are segmented, the carrying capacity is improved, the transmission structure of the five chain is stable, reliable, and the failure rate is lower.

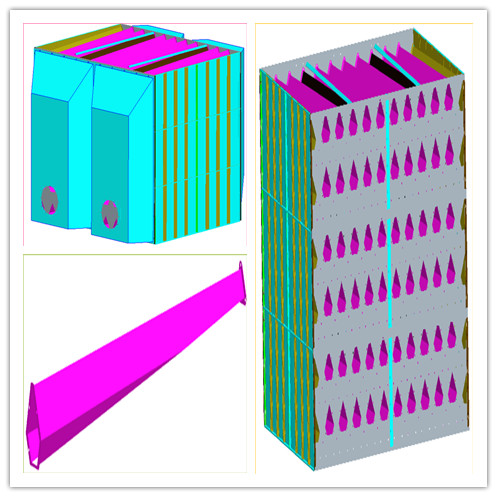

B. Dry layer:

The diamond shaped angle tube structure is used for drying without dead angle, and the drying medium penetrates even, and the drying speed is relatively fast with the cross flow structure 15%-20%.

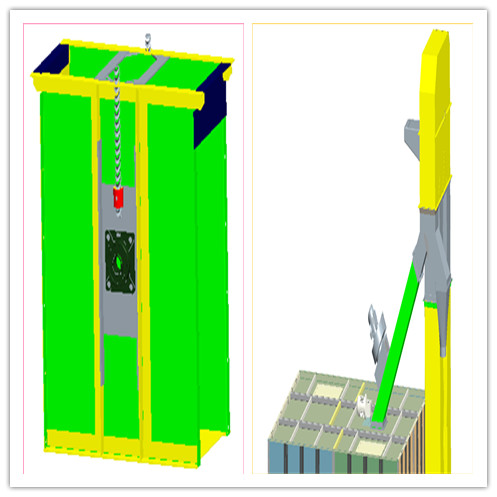

C. Lifting machine assembly, top flow tube:

Simple machine, double barrel design, maintenance is convenient; the large capacity bucket, enhance the capacity, hoist line speed is low, low broken rate, at the top of the stream tube structure with respect to the auger structure, the broken rate is lower; flow pipe and centrifugal extension and have better dust removing effect.

Product Advantage

1. The hot air supply is uniform and the drying speed is increased 20%.

2. The moisture content of grain is more uniform and the quality is high, the energy consumption is low in the same condition 5%~15%.

3. Interior design is reasonable, easy accumulation of grain, easy to clean, not easy to mix.

4. High degree of automation (hot air, valley temperature, moisture on line automatic monitoring, automatic fault alarm, automatic grain circulation, feeding, automatic shutdown system), the whole process of grain drying worry.

Company Information

Realife company is one of 2015 Shandong Province agricultural machinery and equipment R&D project enterprise.Company has a management team with many years of experience in dryig machinery industry. It also hired a lot of experienced R&D and manufacture experts from domestic. The company was established in less than a year.

It developed with independent intellectual property rights and patent products, 4 series of products have been developed for 6T-35T low temperature circulation type, 10T-35T low temperature mixed-flow type, 1T-5T type and 100T-1000T high temperature continuous type etc.

Packaging & Shipping

1. Tell your detailed address.

2. Tell your airport name.

3. Tell your delivery port.

We will deliver the product within 15 days after receiving advance payment.

FAQ

1. What is your MOQ?

Normally our MOQ is 1 set.

2. What is your delivery time?

We deliver in 15 days after receiving the deposit.

3. Can we visit your factory?

Yes, of course. You are welcome at any time. Please contact me and we'll pick you up there.

4. Can you offer easy worn parts?

Yes, we offer easy worn parts with the products.

5. How is your After-Sale service?

Engineers available to service machinery overseas. And if you have any questions, you can contact us at any time.

Please contact me!

![18578031_163654351136_2[1]_](/data/uploads/2016/07/26/1469496348430292.jpg)